The Only One One-Stop Supplier and Manufacturer of Trading Card,Sport Card and Gaming Card Supplies in China

With 16 years of manufacturing and design experience, PYP factory specializes in card holders, boxes, sleeves, binders, and various display cases.

GERMANY

In der Meile 11 44379 Dortmund

USA

133 W Garvey Ave b 1302, Monterey Park, CA

JAPAN

579-8063東大阪市横小路町 5-10-20

Three Overseas Storage Warehouses

Free full-process guidance for buyers on product import procurement procedures

OEM/ODM Custom

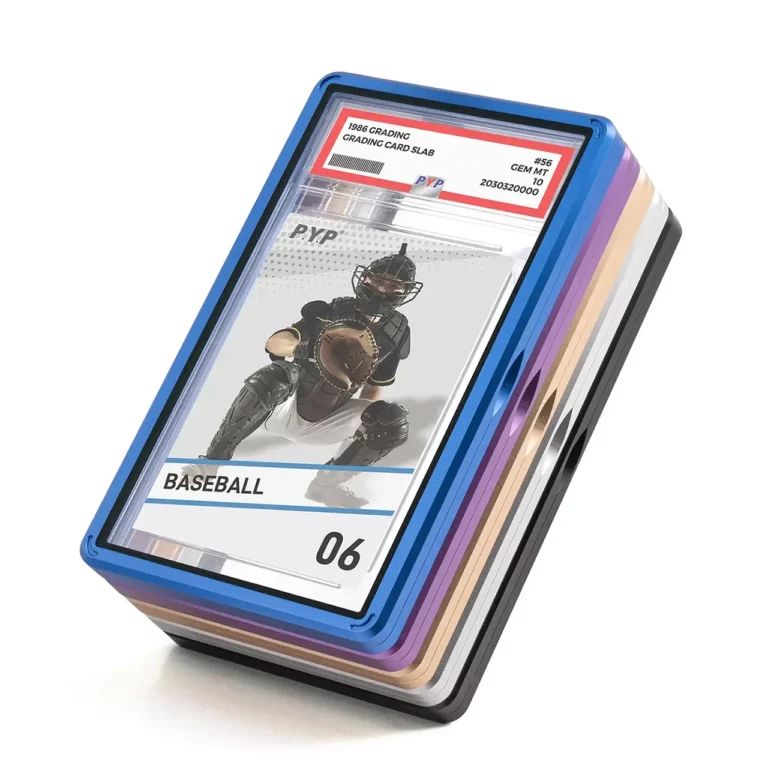

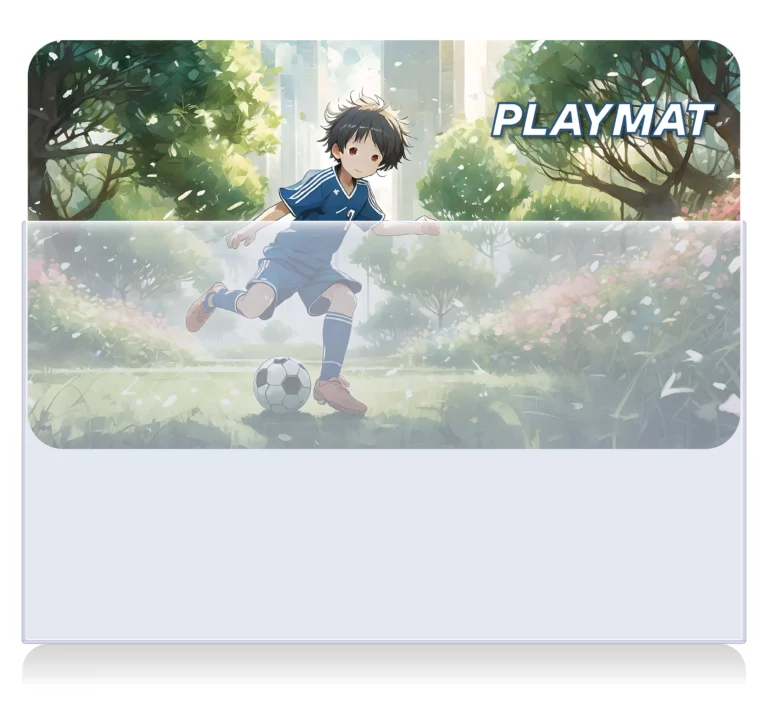

Your Collection Deserves Premium Protection

—Explore Our Top 8 Essential Solutions

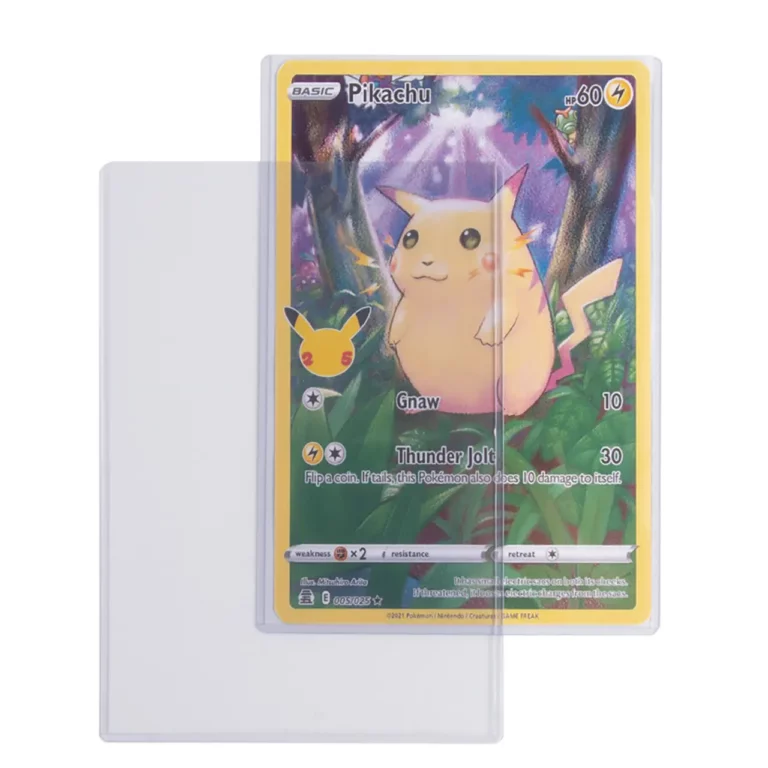

Trading Card Supplies

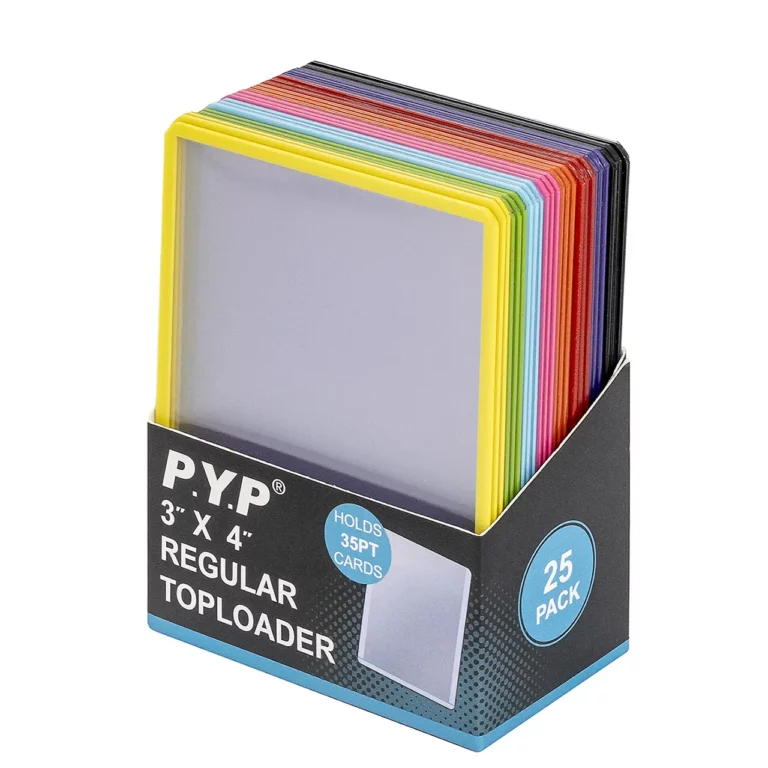

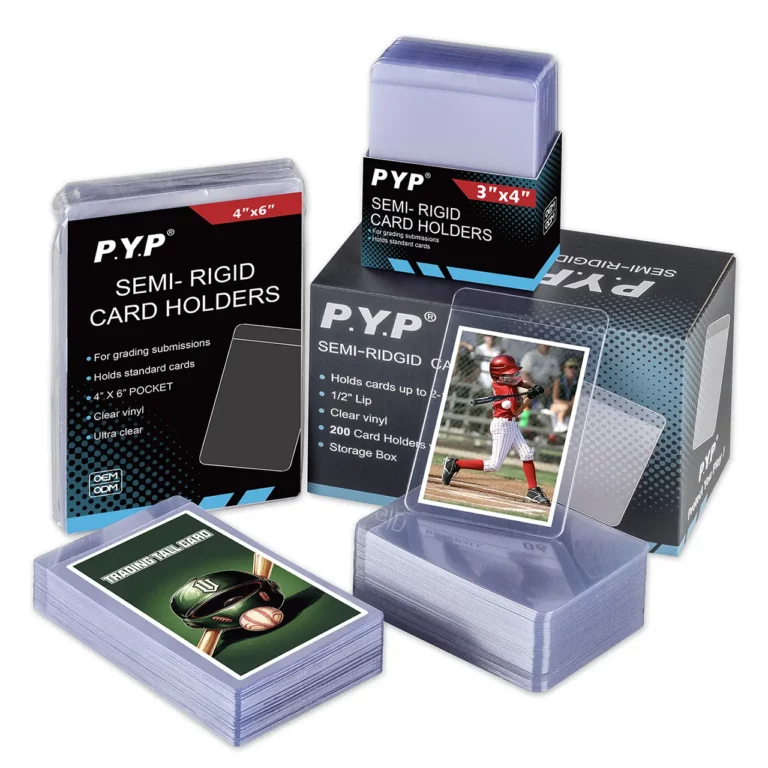

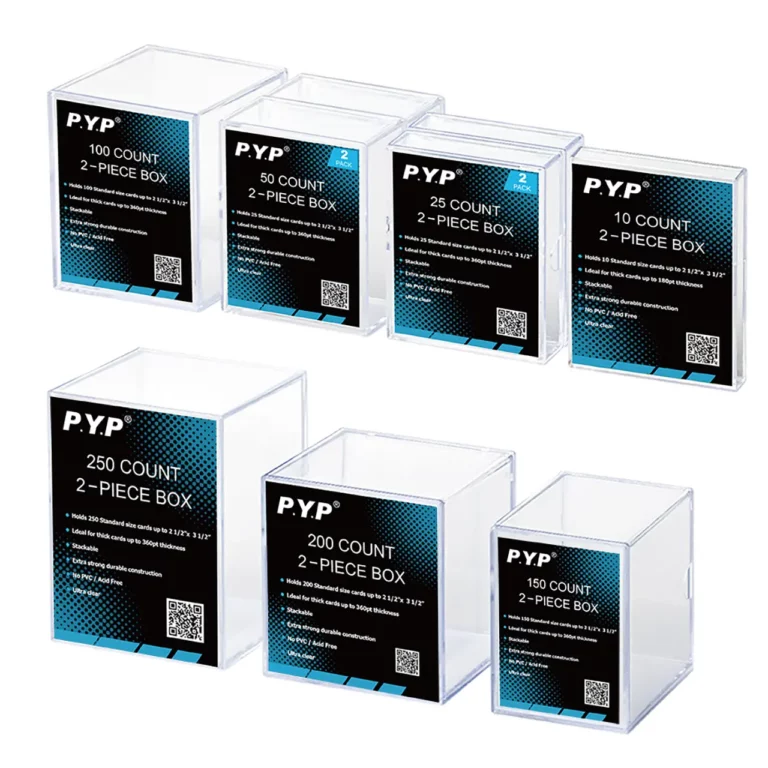

Magnetic Card Holders,Graded Card Holders,3X4 toploaders

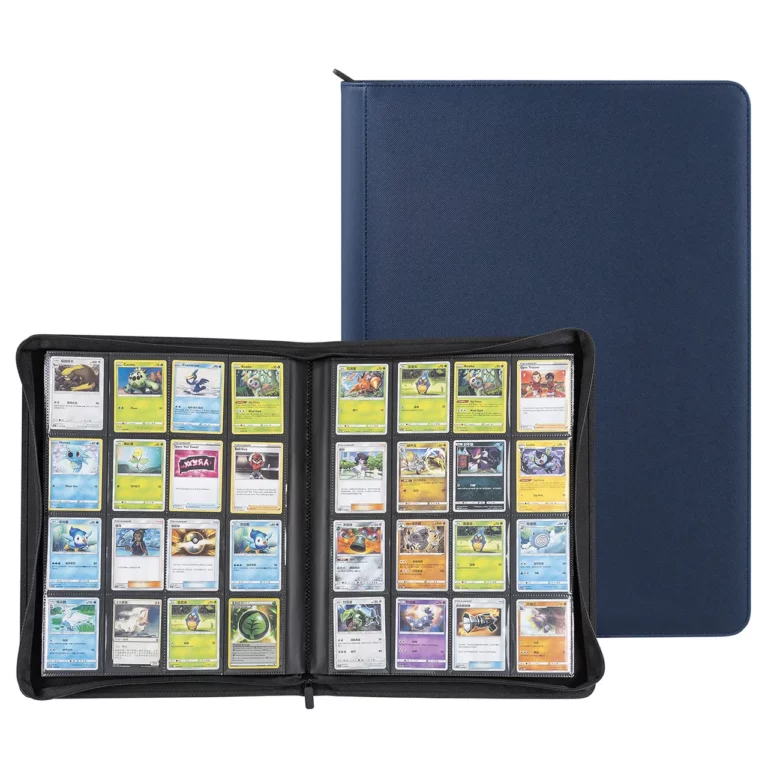

Trading Card Sleeves, Cases,Semi-Rigid,Binder

Gaming Card Supplies

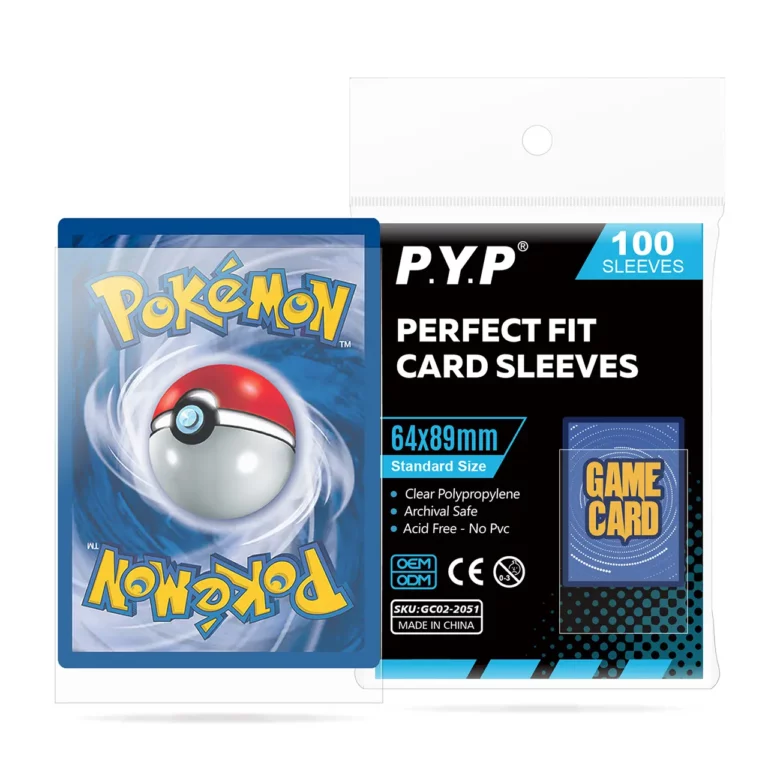

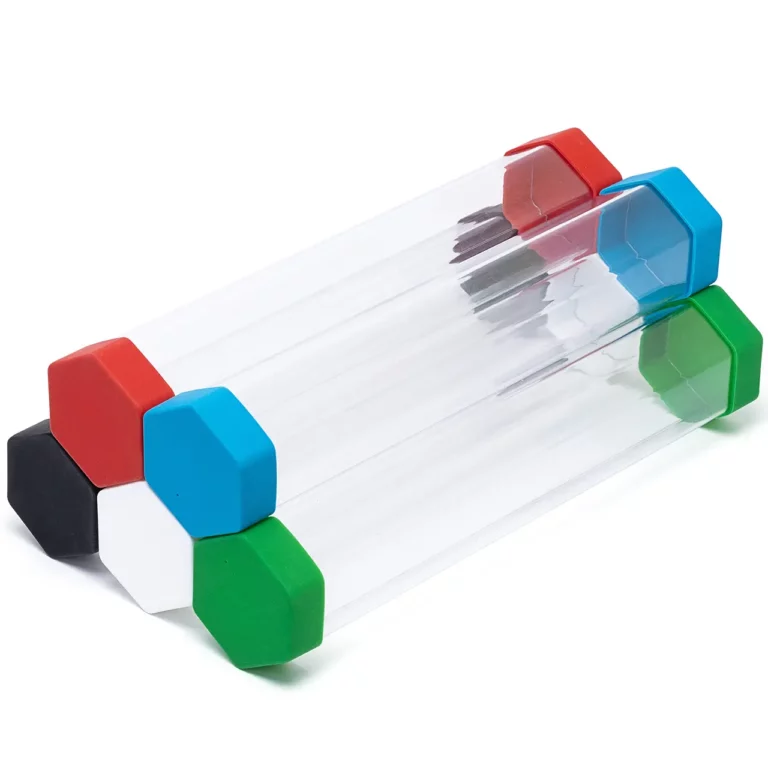

Matte Card Sleeves,Perfect Fit Card Sleeves,Card Deck Box

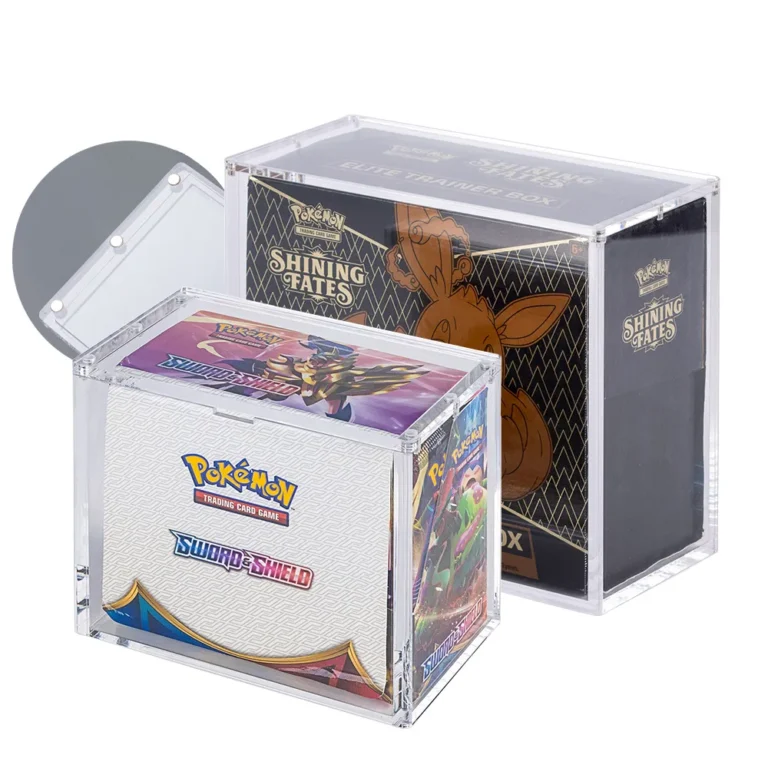

Card Deck Case,Card Binder,Booster Displays

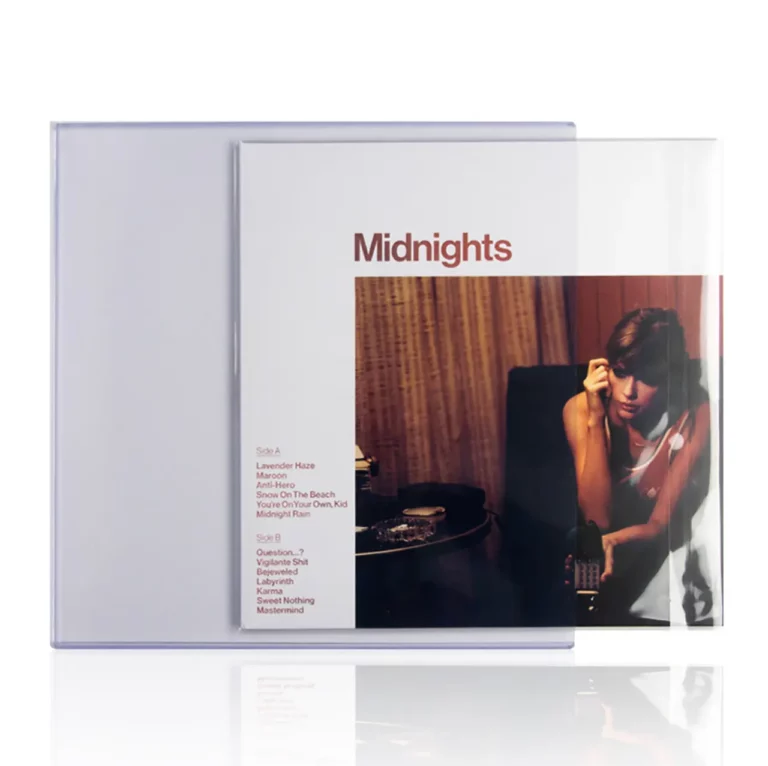

Record & CD/DVD Muisc Supplies

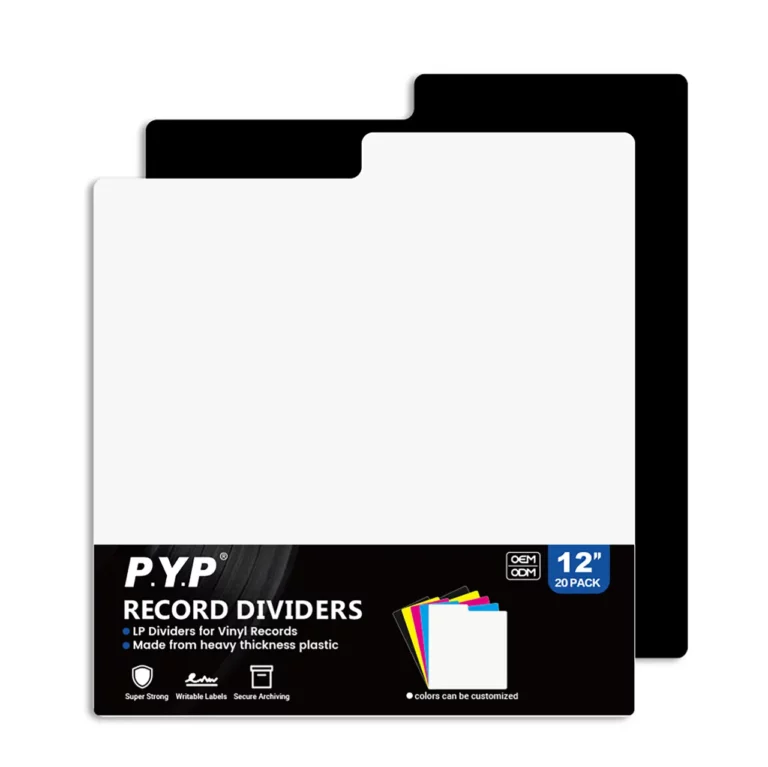

Viny Record Inner Sleeves,Out Sleeves,Toploaders,Dividers,

CD Inner Sleeves,Out Sleeves,Vinyl Record Adaptor

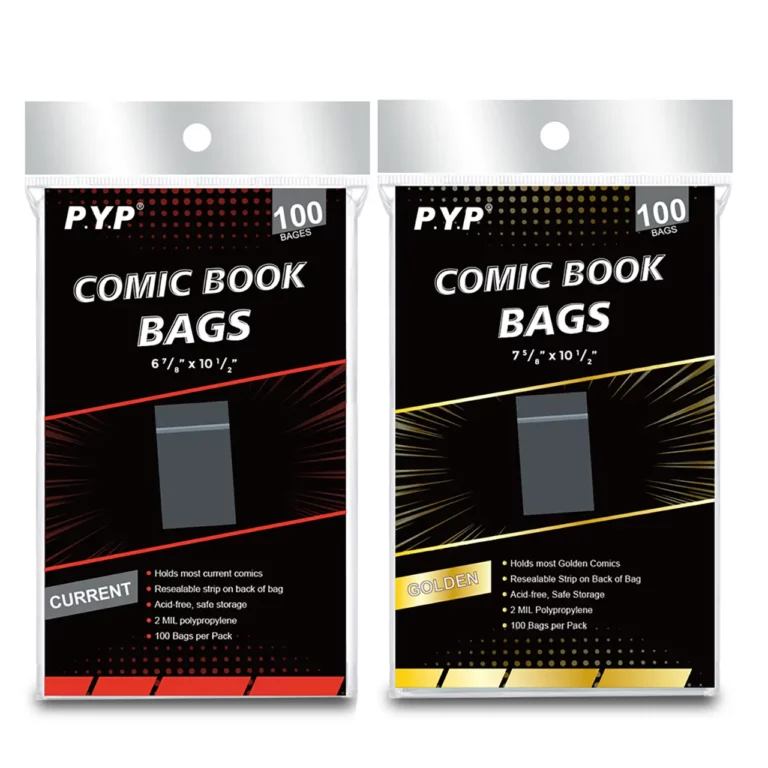

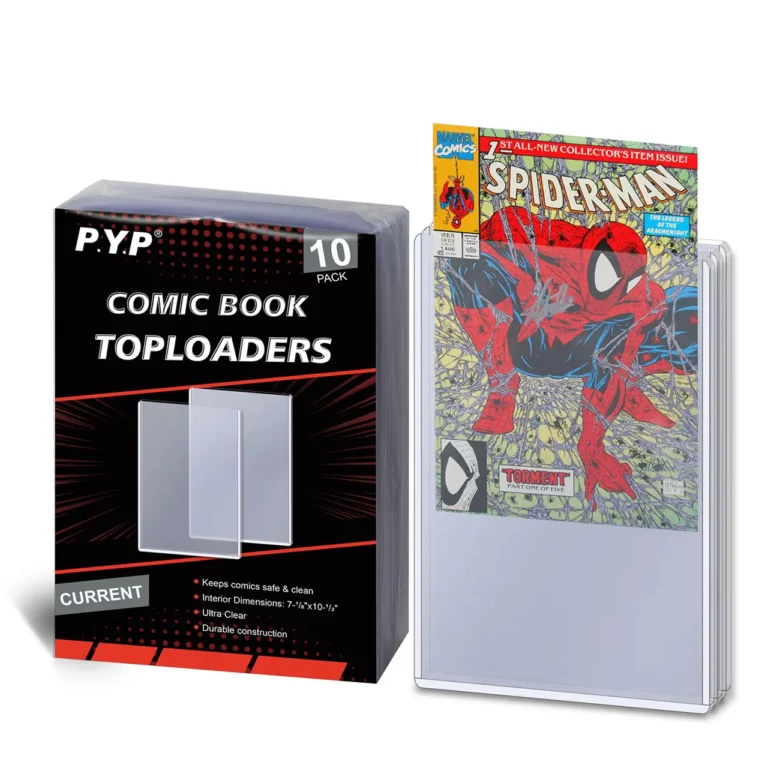

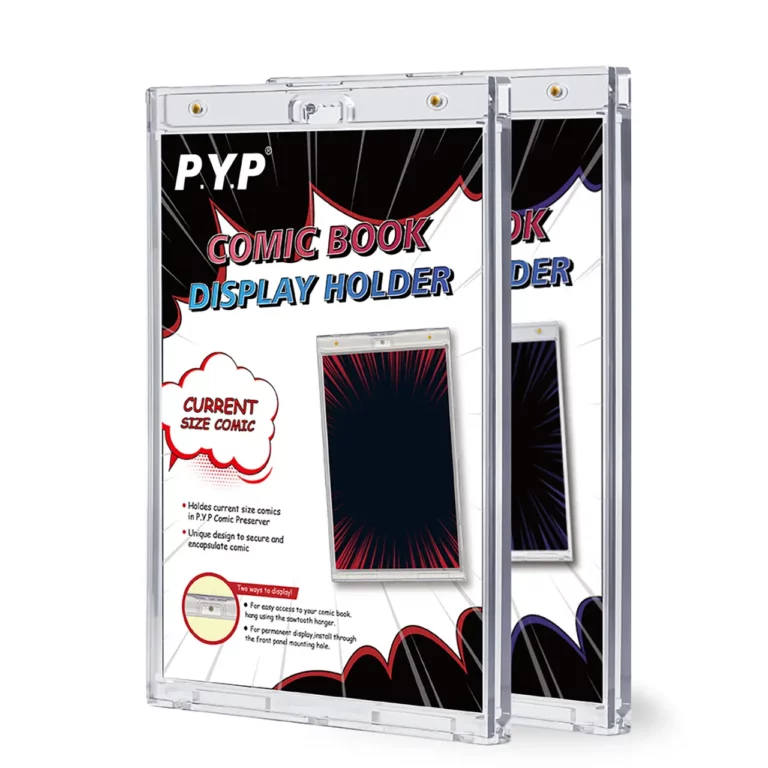

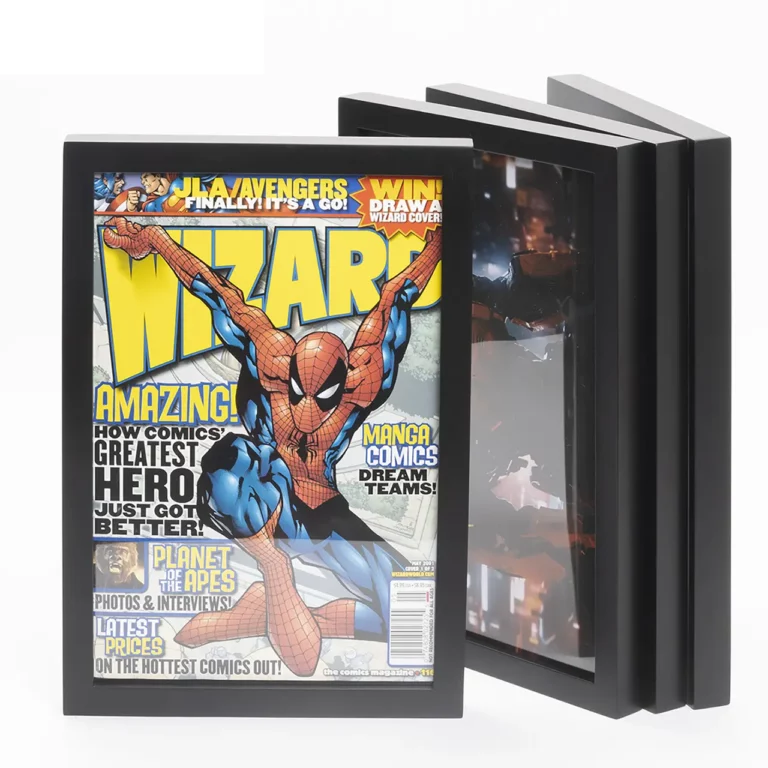

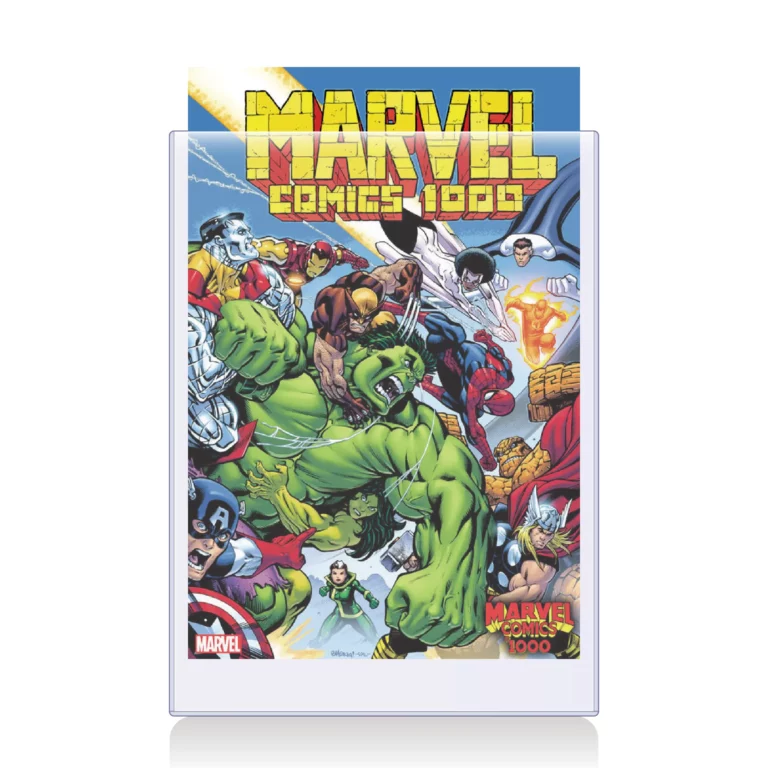

Comic Book & Magazine Supplies

Comic & Magazine Bags,Backer Boards,Magnetic Holders

Toploaders & Dividers

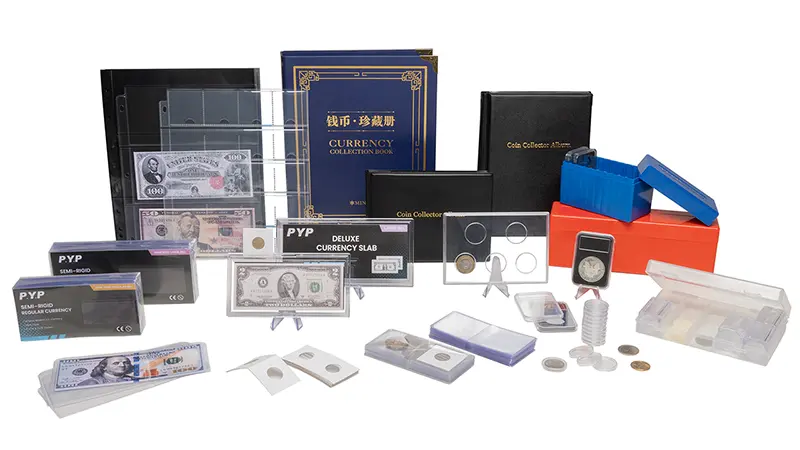

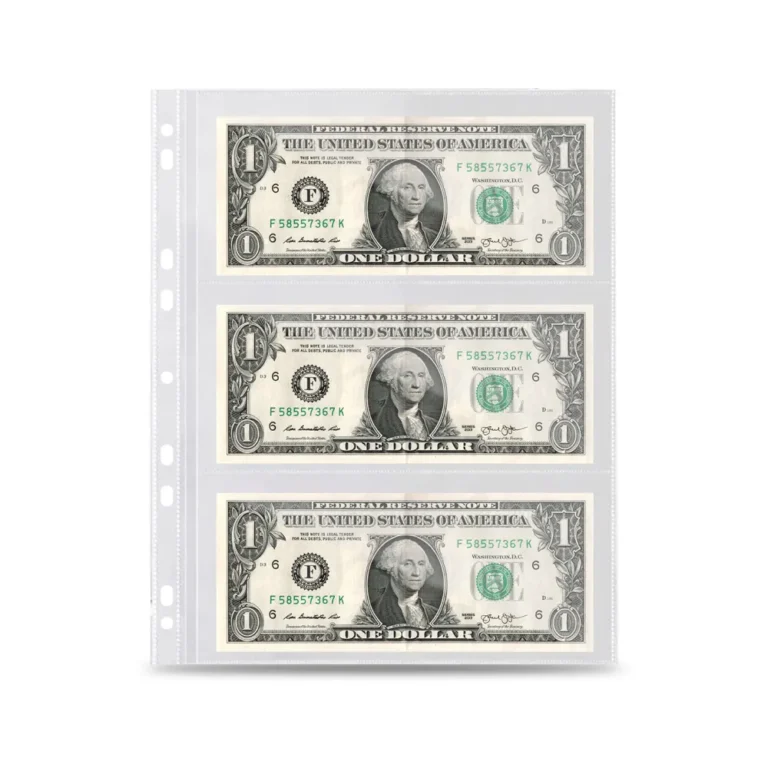

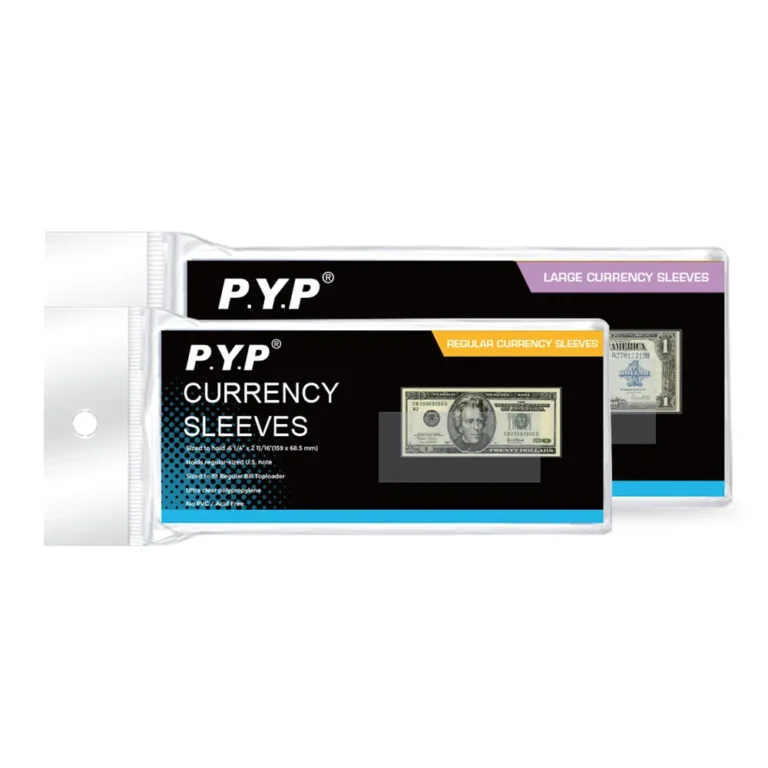

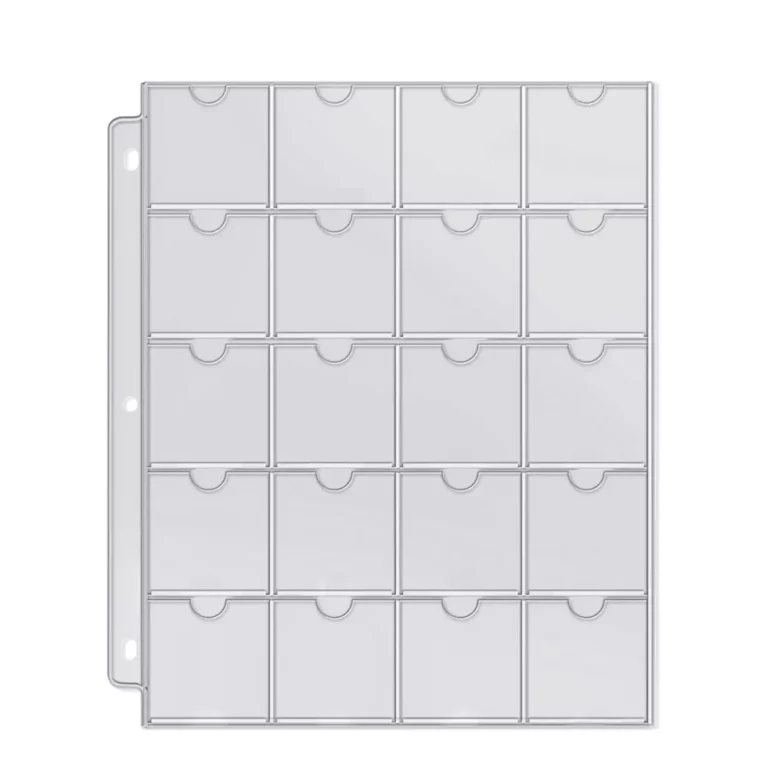

Coin/ Currency & Bill Supplies

Coin Flips,Coin Slab Display Holder,Coin Tubes,Currency Slabs,

Currency Toploader Holders, Pages & Album

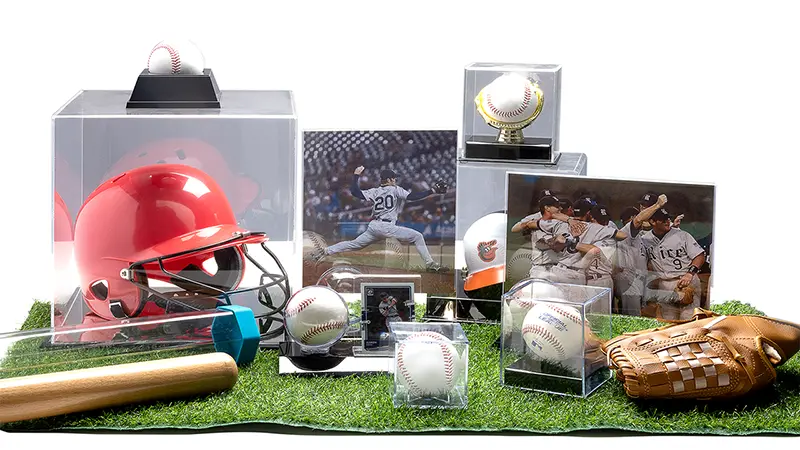

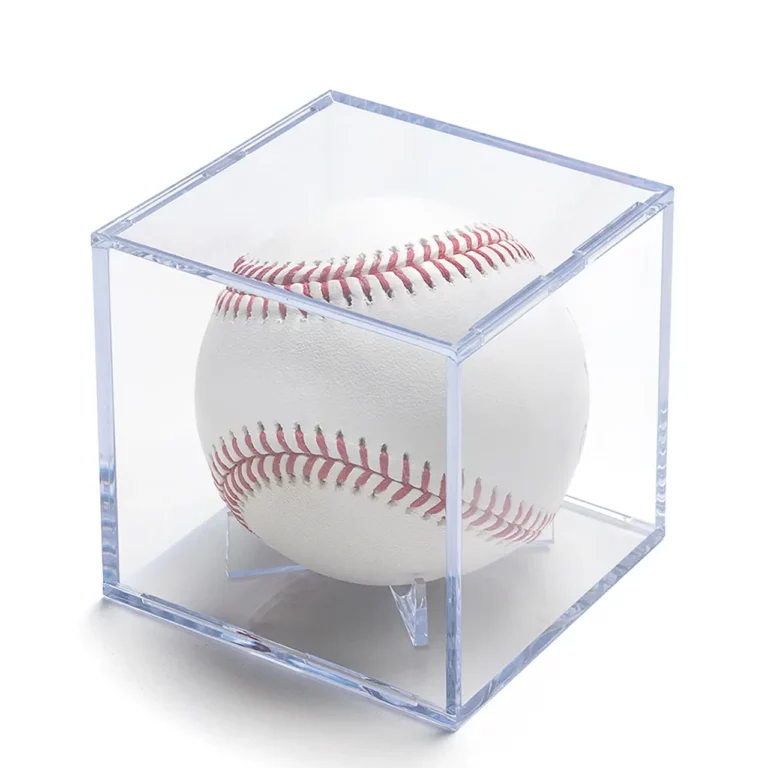

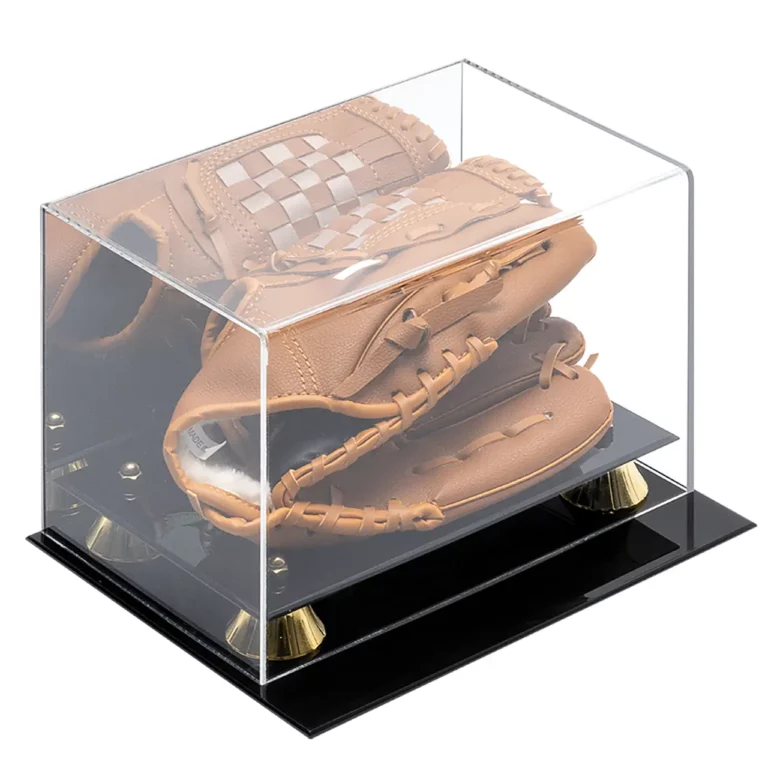

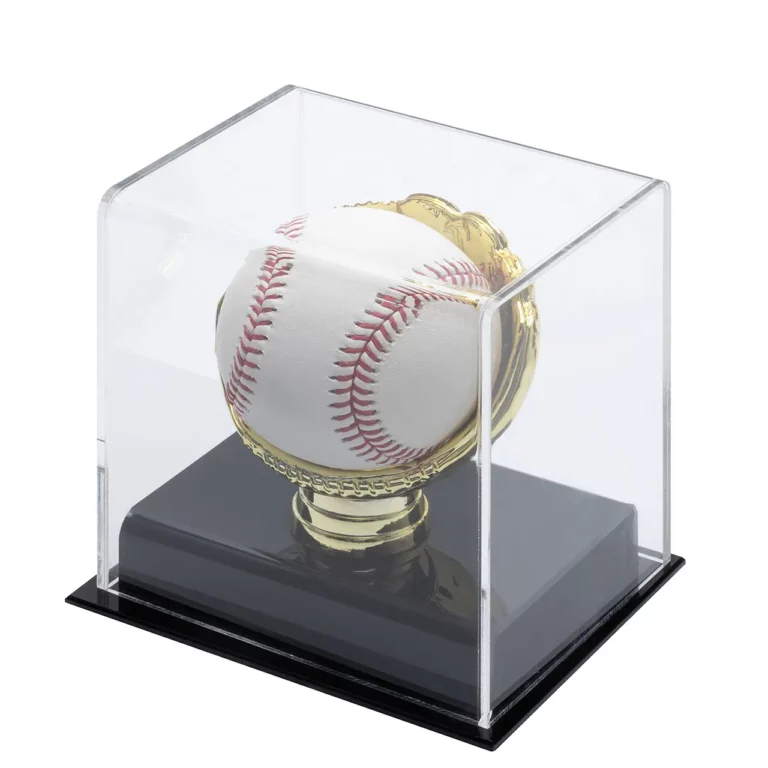

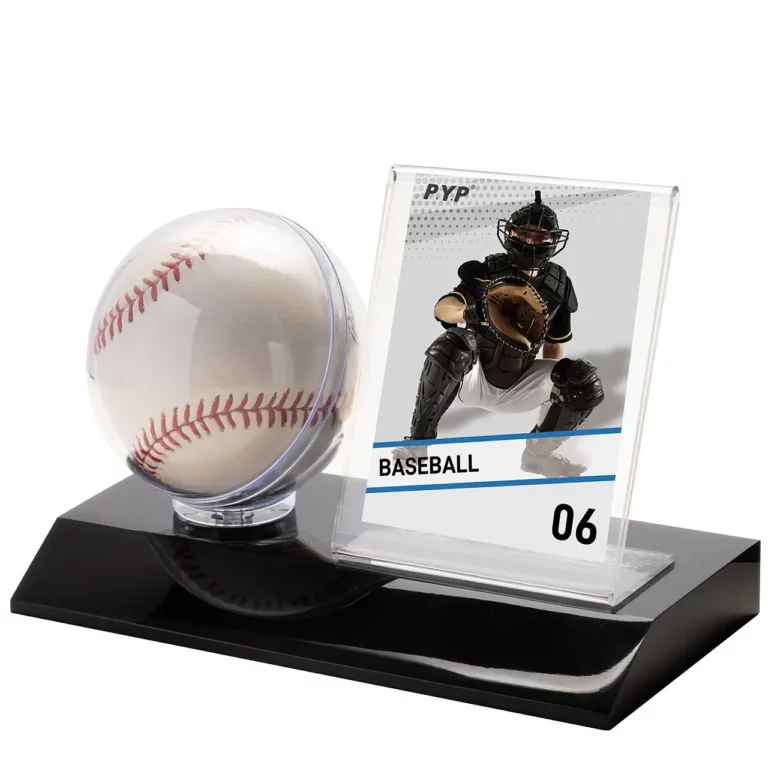

Memorabilia Displays

Baseball,Catcher Gloves,Helment Display Case Display Case,Baseball Bat Tubes

Hockey Puck,Basketball, Golf Ball,Football Display Cases

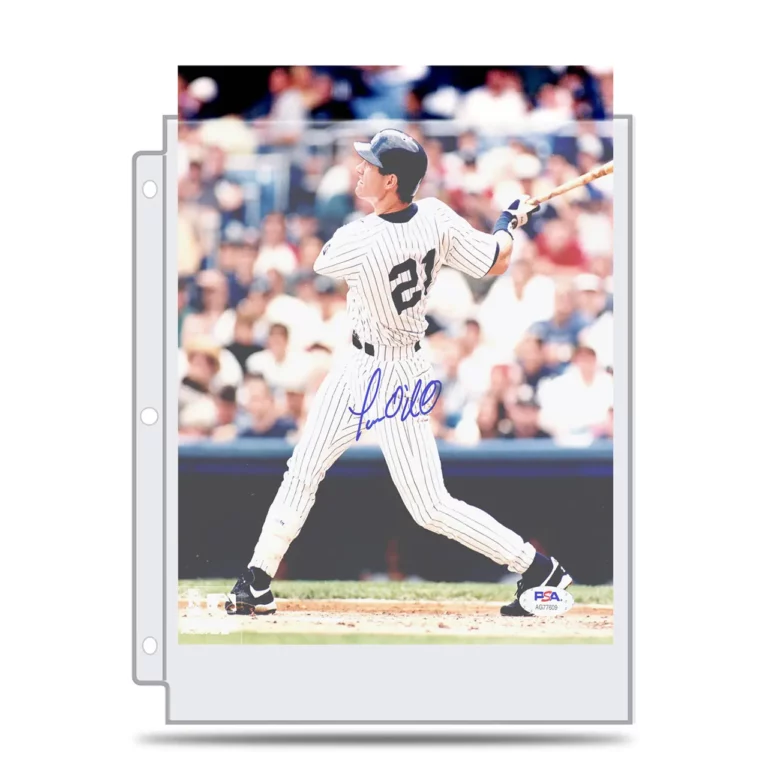

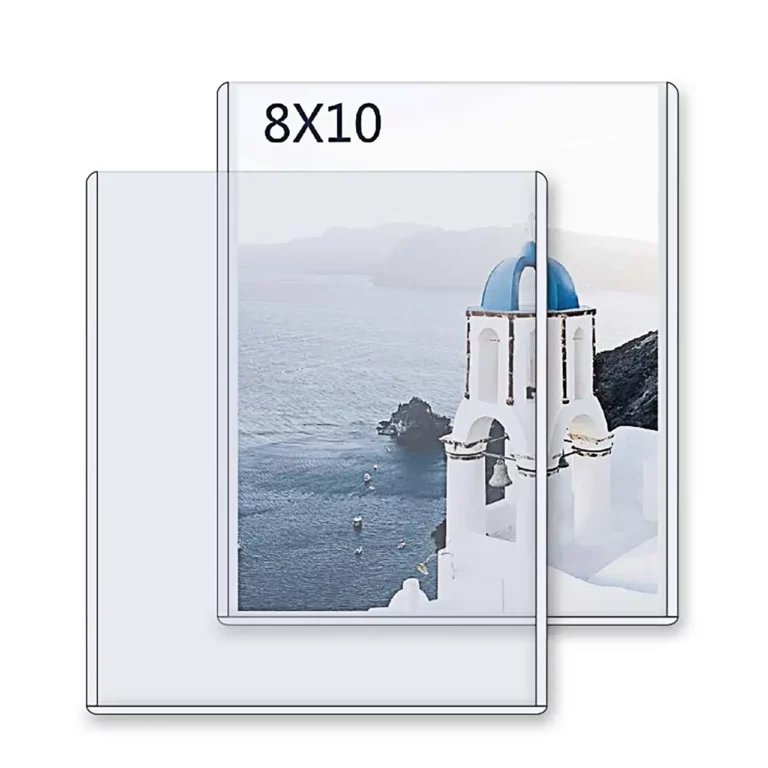

Photo,Postcard Supplies

Photo, Photocard Sleeves,Photo Toploaders,Photo Magnetic Holder

Photo Pages, Postcard Toploaders

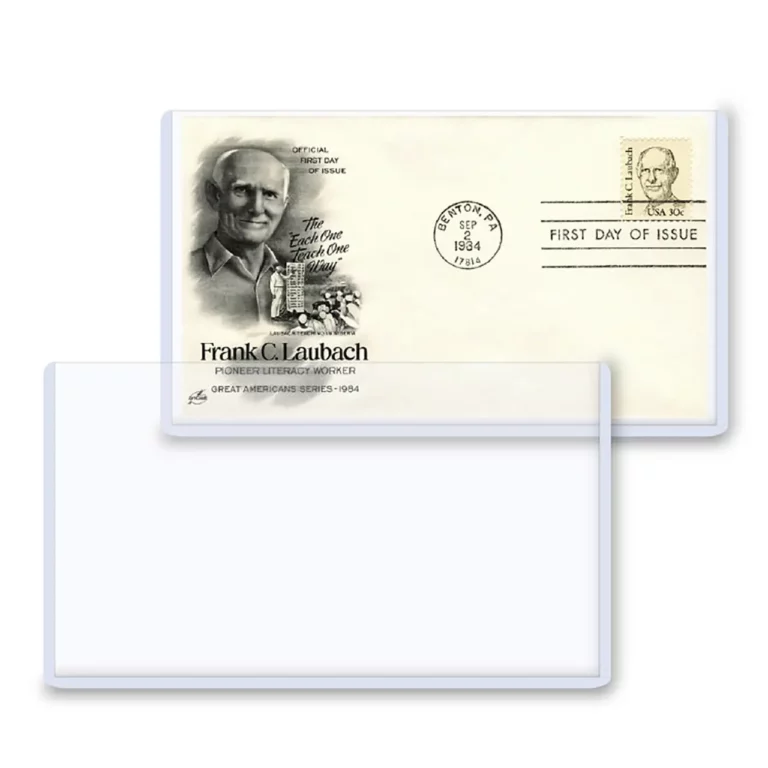

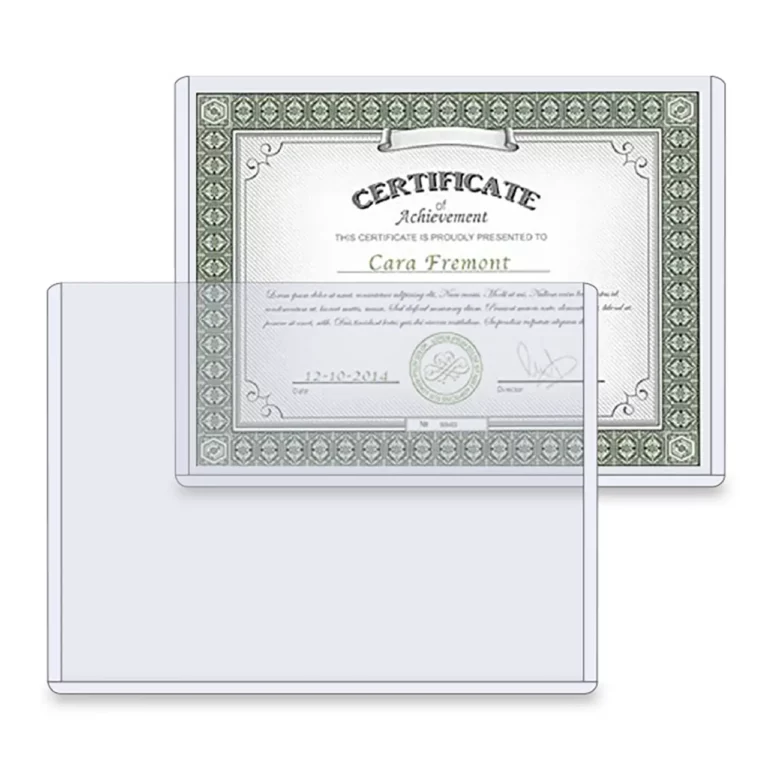

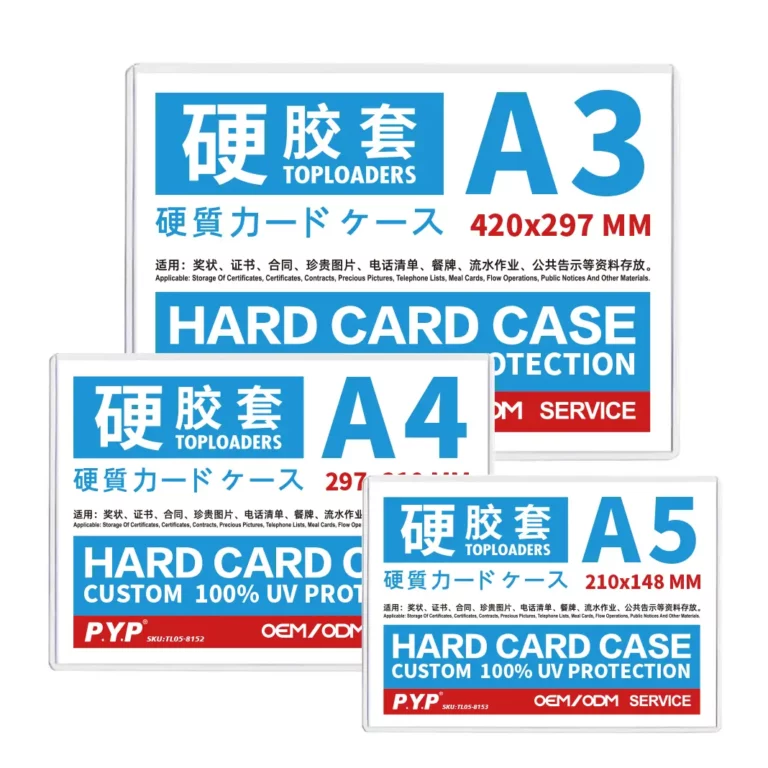

Toploaders & Toploaders Holders

24×36″,24×70″,11×17″ Poster Toploaders,Ticket Toploaders,Map Toploader

First Day Cover Toploader,Document Toploaders,Pennant Toploader

Trusted By Top Brands:

Custom Protection for All Collectibles

9-Step Quality Control

Pass 9 durability tests, ensure our collectible protectors offer maximum protection.

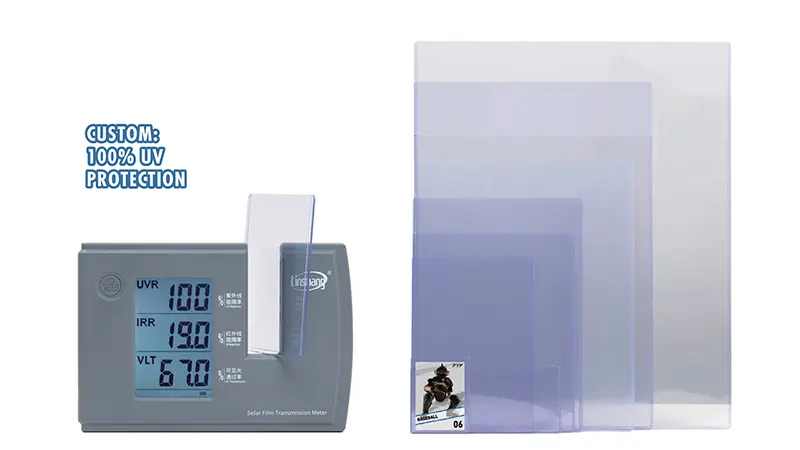

Museum-Grade Protection

Acid-free protection. 30% clearer, 35% more scratch-resistant. Exclusive materials for your collectibles.

R&D-Driven Protection

200+ self-developed molds for exclusive, high-quality protection of all collectibles.

Hassle-free Services

We offer 12-hour response, 2+ yearly on-site visits, and free import guidance for smaller buyers, ensuring smooth operations and minimizing after-sales issues.

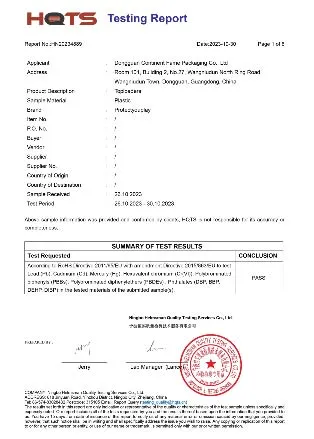

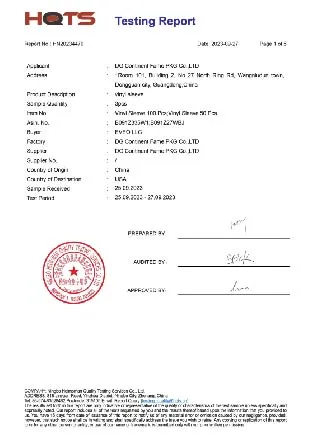

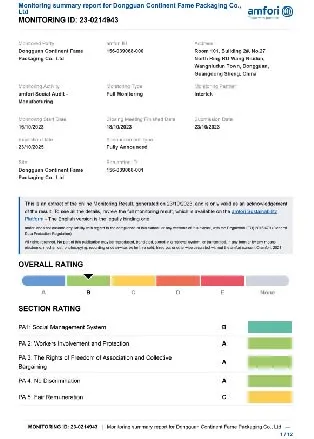

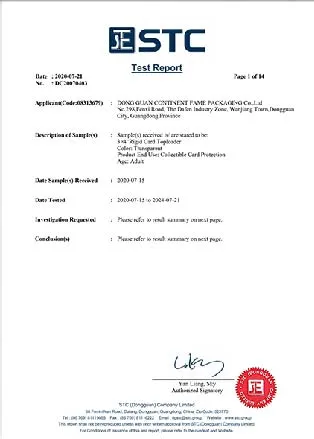

CERTIFICATES

TESTING REPORT

The P.Y.P ® factory has obtained ISO9001:2015, WCA, TUV, and BSCI (Grade B) corporate certifications.

Our products have passed SGS, REACH, RoHS, CE, and UKCA quality inspections.

The company has an independent product R&D department with over 80 appearance patents and utility model invention patents, and our excellent R&D innovation capabilities are currently leading the industry.

EXHIBITION

See us in action at these events

VIDEO

Production video and trade show video

PYP Manufacturing Process

Products-Trading Card Supplies

Products-Gaming Card Supplies

Factory Manufacturing Videos

Global Exhibitions

NEWS

Latest news and stories

Group press release Oct 14,2024

How Our Factory Scales to Provide Premium Toploaders for Global Brands and E-Commerce Sellers

Group press release Oct 14,2024

How to find Card Sleeves manufacturer in China

Group press release Oct 14,2024

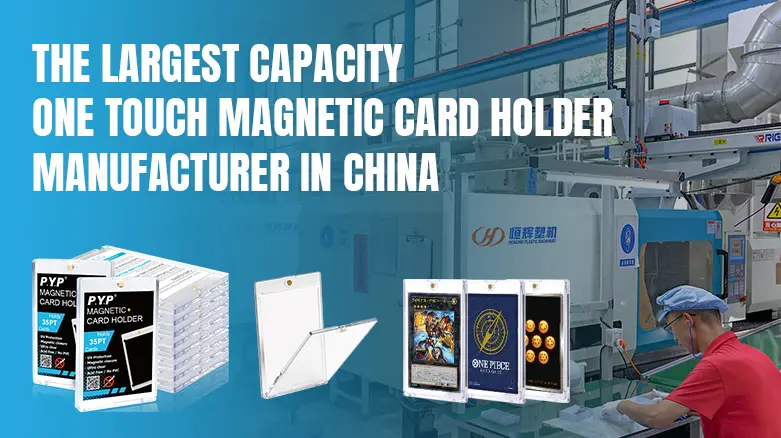

The largest capacity One Touch Magnetic Card Holder manufacturer in China